This item is described formally in the text of the next image below, belonging to the issued patent. I will try to describe it more informally in this space.

I had initially in mind a lock for the familiar Manila envelope, which has had to add a readily broken metal clasp or a likewise obtrusive winding string.

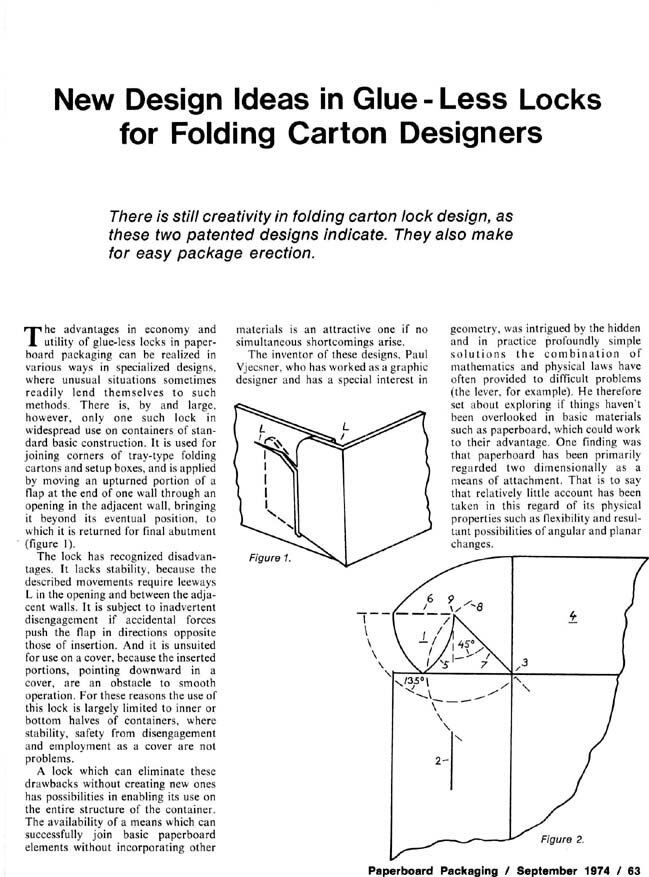

The present lock takes advantage of the glued overlap (12,13)—by which parts of "wall" 11 are joined—to add the vertical slit 10 in which to insert the lock. That lock is located in envelope-flap 3 where it is cut out as shown by the solid lines. Area 9 on top is empty and not strictly needed. What is needed is fold or bend 5—coinciding in locked position with slit 10—an obtuse angle of that fold 5 with the edge of the lock at 7, and fold 2, by which to bend the lock outward.

The significance of these is seen in the figure omitted for some reason at left from my original drawings and added here below the text-page as FIG.3, next to what was instead FIG.4. There FIG.3 shows in three dimensions the insertion of the lock into slit 10 after closing the envelope. Area 11 at the slit merely reveals a cut-out part of the envelope-flap, as it does in FIG.4 (at left FIG.3), which depicts the locked envelope. Now the reason for the low angle at 7, or 15, is that on trying to open the envelope-flap, the motion would be perpendicular to it, for a direction the downward angle at 7, or 15, of the inserted lock will prevent.

It should be mentioned that the lock can be used on other envelopes that have a closing flap. In cases of stiff material, the above fold 5 may need to be a sharp one, compared to a mere bending in paper envelopes. Slit 10 can for similar reasons be a leftward curving arc, enabling easier access.

It should perhaps also be said that the lock is swiftly disengaged by flipping it outward at edge 8, in resemblance to its insertion pictured at far left.